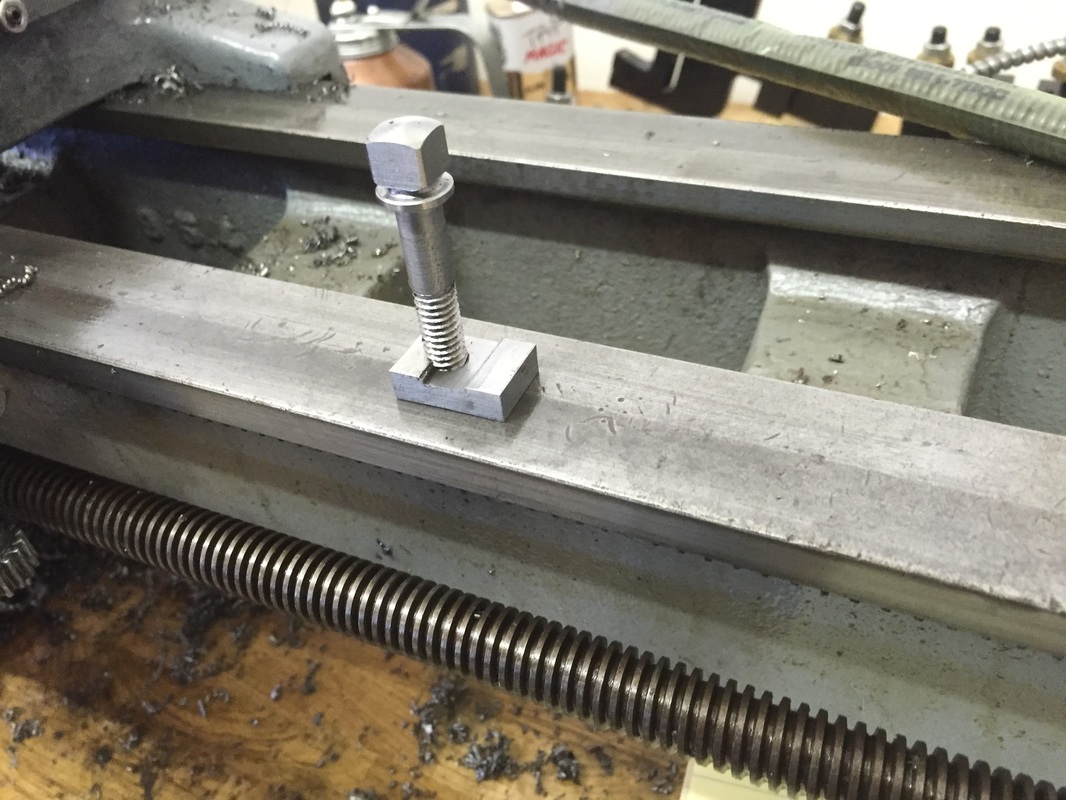

I started off making a few bolts based on the plans from Tom's Techniques for the Atlas micrometer stop. Two (made to the print) are intended to be for a micrometer stop when I get around to making it. The third was made longer for a carriage stop, though the print specification for length would have worked fine in retrospect. My die cut rough threads, but they're acceptable. If I'm ambitious, I'll make another set with a newer (sharper) die. The heads were cut in the CNC mill, easy work to make perfect .375" square heads once I had a good setup to hold them vertical.

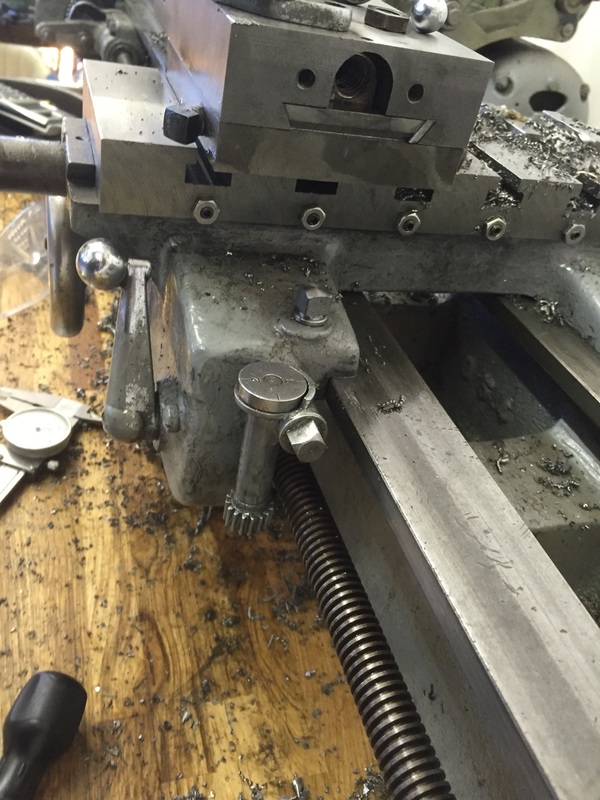

My machine came without a carriage clamp (and lots of other parts) so I decided to make up my own. I made a drawing, but ended up modifying it heavily. It works well, but could clamp a little harder. Tom recommends heat treating them, but I haven't bothered yet.

I shaped a groove in the center to ensure that the clamp part bears on the underside of the carriage and the ways separately. If I crank on the hand wheel, I can move the carriage. I still consider it a huge success. At some point I may machine the underside of the carriage so that it's flush with the bottom of the ways, because it's a bit proud. I believe this is what's affecting the clamping force.

I shaped a groove in the center to ensure that the clamp part bears on the underside of the carriage and the ways separately. If I crank on the hand wheel, I can move the carriage. I still consider it a huge success. At some point I may machine the underside of the carriage so that it's flush with the bottom of the ways, because it's a bit proud. I believe this is what's affecting the clamping force.

RSS Feed

RSS Feed