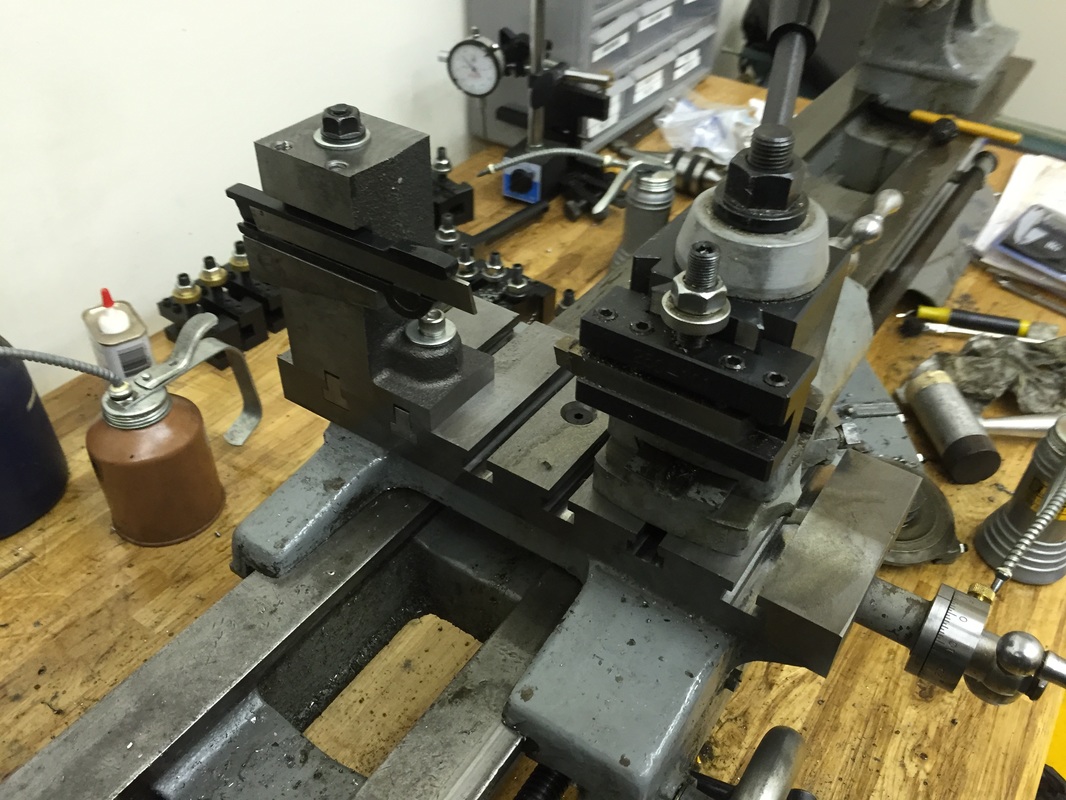

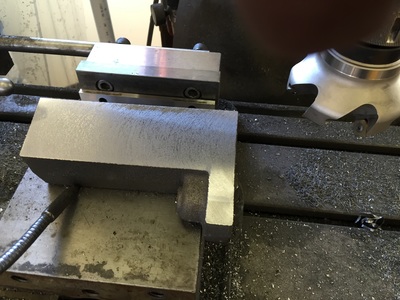

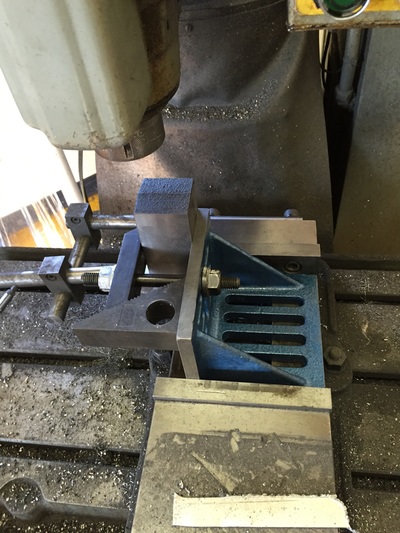

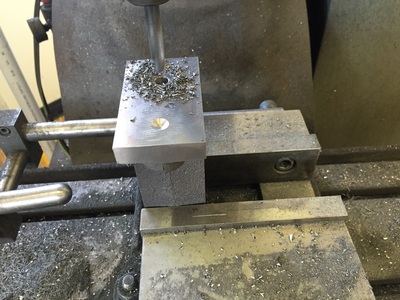

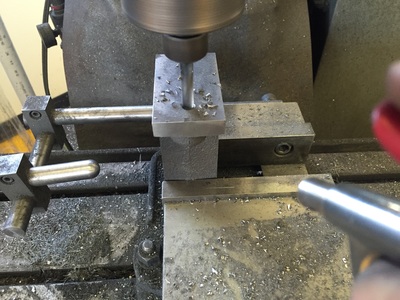

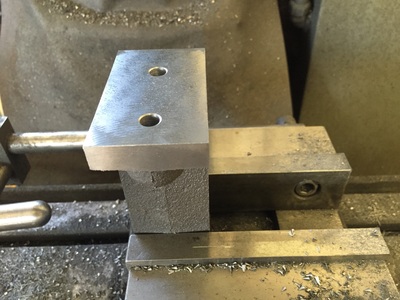

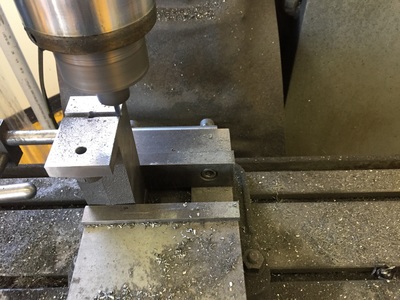

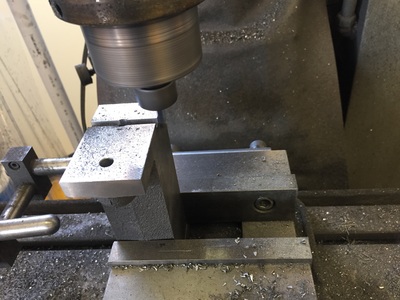

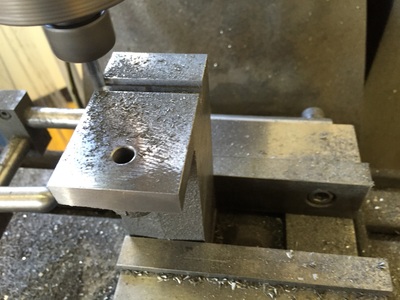

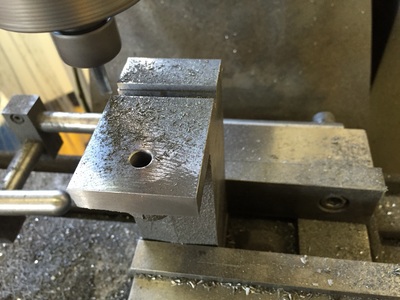

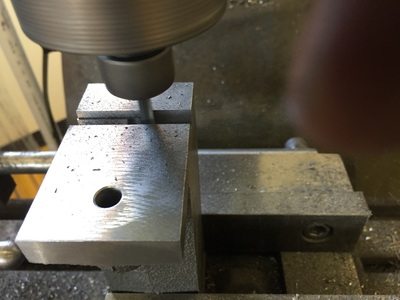

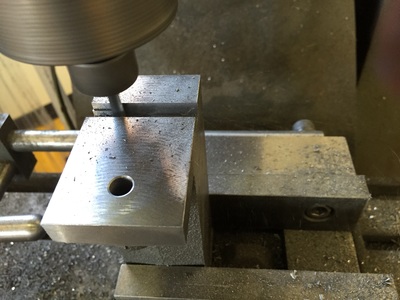

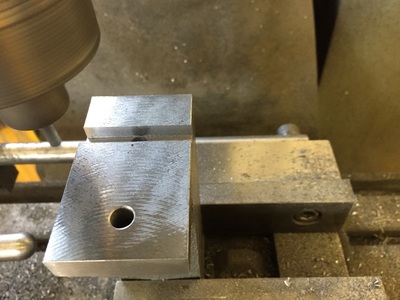

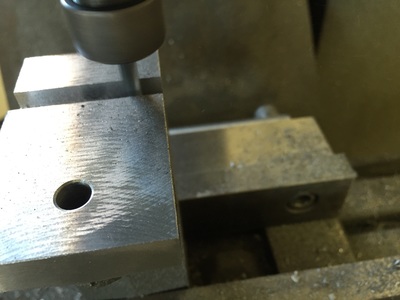

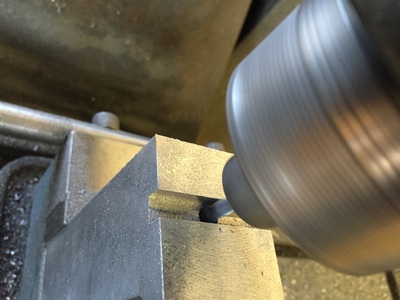

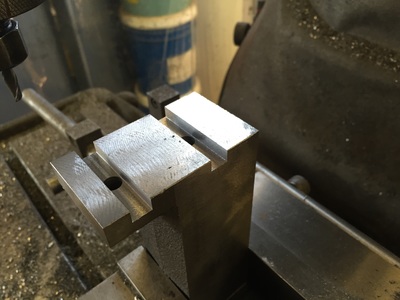

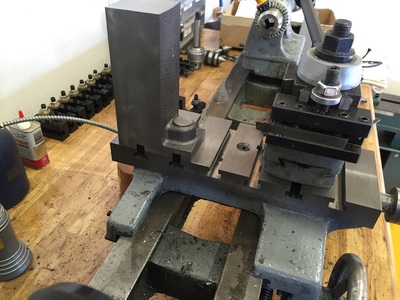

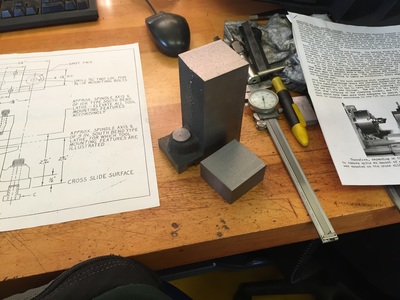

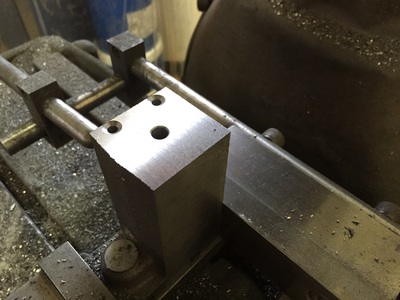

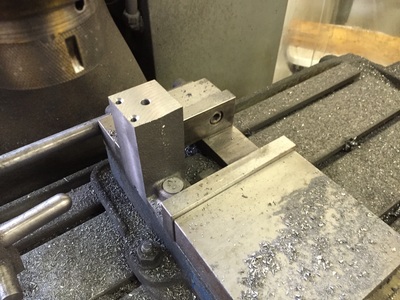

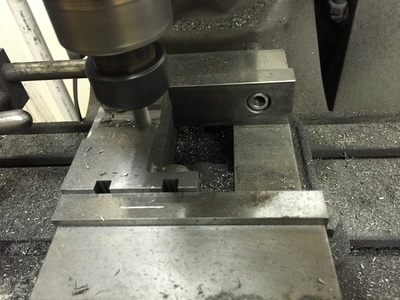

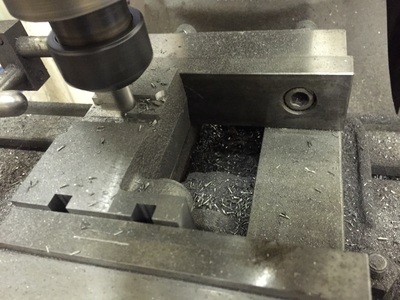

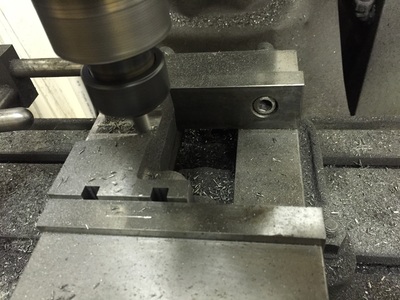

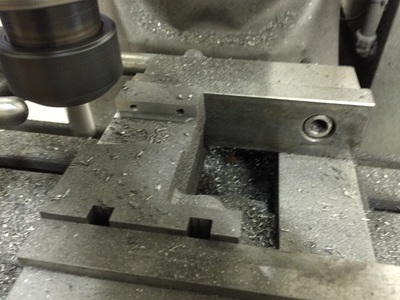

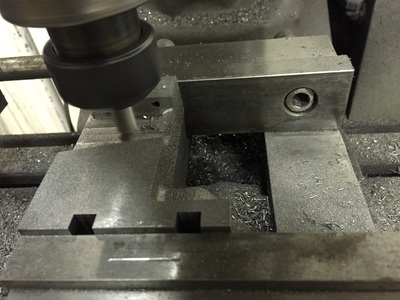

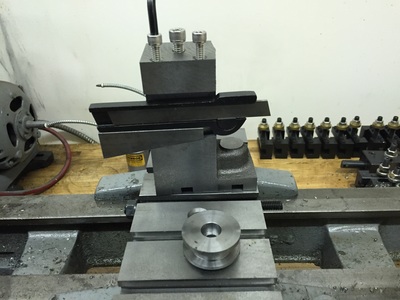

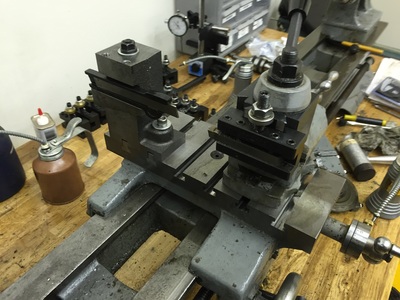

After I completed the cross slide, I moved on to the compound rest project. I made a pair of t-slot nuts to mount it in the cross slide t-slots, and did some machining. This was almost all done on the CNC mill. It went much faster than the cross slide, but was also relatively simple. Again, the 3" face mill ripped through the cast iron, and much of the project is machining the casting faces. There is some slotting and some drilling, but that wasn't a huge part of it. Finally, a wedge had to be made. That involved some shaper work (easier than fixturing the piece on the mill), which was delicate due to the setup, but came out excellently. Unfortunately, this part still has not been installed because I broke a tap on the last tapped hole. It's currently at a shop with EDM capabilities. It took quite a while to find one locally, so it sat on the bench for a while. A failed attempt to make my own EDM put this project on hold until the shop could be located. I hope to have it installed in a few weeks once it's back from the machine shop.

About UsImproved Parts is all about exploring interesting and practical manufacturing techniques, solving unique problems that crop up in our everyday life, and GOING RACING! Archives

March 2016

Categories |

RSS Feed

RSS Feed